Float Cabin Living: How do you get power? Propane

In the city, we were used to natural gas for heating and appliances, but propane in large tanks was new and a little scary.

Now that we are more comfortable with propane, we use it for the stove, a refrigerator, lights and other applications.

|

| Wayne at the outdoor propane shed. |

Getting propane up the lake is a lengthy process.

|

| Our Hewescraft lake transport. |

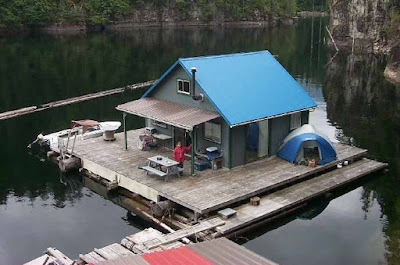

We use 20 pound tanks for our BBQ. There's nothing like a grilled dinner on a cold winter night. The front porch gives Wayne a protected spot to work his dinner magic. A 20 pounder costs $22 and lasts about three months. That's pretty economical.

We use 20 pound tanks for our BBQ. There's nothing like a grilled dinner on a cold winter night. The front porch gives Wayne a protected spot to work his dinner magic. A 20 pounder costs $22 and lasts about three months. That's pretty economical.We use 40 pound tanks for lights, refrigeration and cooking. A 40 pounder costs $44 and lasts about a month. Again, that's an economical source of energy. We found an auto-switch Y-valve for continuous propane distribution.

It's tough in winter to generate enough solar power to run electric lights for more than a short time each night. Even on a sunny winter day we only get about two hours of direct light. Our winter alternative is propane light.

It's tough in winter to generate enough solar power to run electric lights for more than a short time each night. Even on a sunny winter day we only get about two hours of direct light. Our winter alternative is propane light. In our kitchen we have a Premier propane range. It has four burners and an oven with two racks and lots of room that makes baking easier than in my old oven. The pilot lights use minimal propane and make cooking easy.

In our kitchen we have a Premier propane range. It has four burners and an oven with two racks and lots of room that makes baking easier than in my old oven. The pilot lights use minimal propane and make cooking easy. We upgraded our old 8 cubic foot fridge to 13 cubic foot Unique propane refrigerator. Now we have all the refrigerator and freezer space we need.

We upgraded our old 8 cubic foot fridge to 13 cubic foot Unique propane refrigerator. Now we have all the refrigerator and freezer space we need.How does a gas flame create cooling. The Gas-Fridge.com website says: "The basic principle is through evaporation. An ammonia mixture sealed inside the cooling unit is heated by a gas burner, which causes it to circulate before it evaporates and creates a cooling effect."

We also use Big Buddy portable propane heaters. One use is in our Hewescraft during winter to make our 30 minute boat rides more comfortable. It mounts safely in the front of the boat's cabin. It has auto-shutoff safety features and runs on either canisters or a 20-pound tank.

We also use Big Buddy portable propane heaters. One use is in our Hewescraft during winter to make our 30 minute boat rides more comfortable. It mounts safely in the front of the boat's cabin. It has auto-shutoff safety features and runs on either canisters or a 20-pound tank. A second Big Buddy warms our winter outdoor porch shelter. With a little heat we can still eat outdoors on many nights.

A second Big Buddy warms our winter outdoor porch shelter. With a little heat we can still eat outdoors on many nights.Click below for more information about our various off-the-grid propane uses:

Using Propane for Power

Search for a Propane Refrigerator

Freestanding Propane Range

Kitchen Kapers

Off the Grid Refrigerator Repairs

Propane Lights

Mr. Buddy Propane Heater