|

| Spring 2018 before pressure washing. |

Just like any home, it's only as good as the foundation.

|

| After removing the stain aging was evident. |

Periodically, we've replaced individual boards and a few supports to extend the life of our foundation and deck, but in 2019 it was evident that we needed to do much more.

|

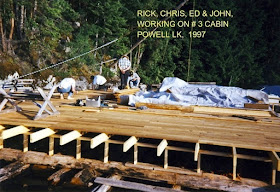

| Our float cabin's raft during construction. |

Crosswise logs and steel cables secure the float logs together. On top, pony walls of vertical then horizontal 2x4s are nailed into the cross-member logs. This provides a level platform for the cabin and deck.

|

| The pony walls are then added to the float log foundation. |

Vertical 2X6" boards are nailed on top of the pony walls. Throughout this process, everything is double-checked to make sure it's level.

|

| To support the deck boards, vertical 2x6s are nailed on top of the pony walls. |

Yellow cedar is best for decking. Next is old growth red cedar. Last is second growth cedar. Most of our foundation was yellow cedar, but a few spots included second growth wood.

|

| A second growth cedar log on top was replaced with an old growth cedar beam. |

Our good friend John (and cabin's builder) replaced our deck. When he took off the old boards, he discovered several supports that needed replacing. In particular, a second growth log was rotten. He chose to replace all 40-feet with milled 6X6" beams.

Here are some related cabin construction posts:

Float construction

Extra Flotation Power

Pumped

Log Burning for Dry Rot

Cable Up - Anchoring System

In Part 2 I'll tell more about the deck replacement process. -- Margy